A Scandinavian district-energy plant venting 90 °C process water once considered it too low for

meaningful recovery. Kaltra installed microchannel heat exchangers that extract 250 kW of duty

and heat incoming make-up water from 40 °C to 70 °C, cutting boiler gas consumption 18 %

annually.

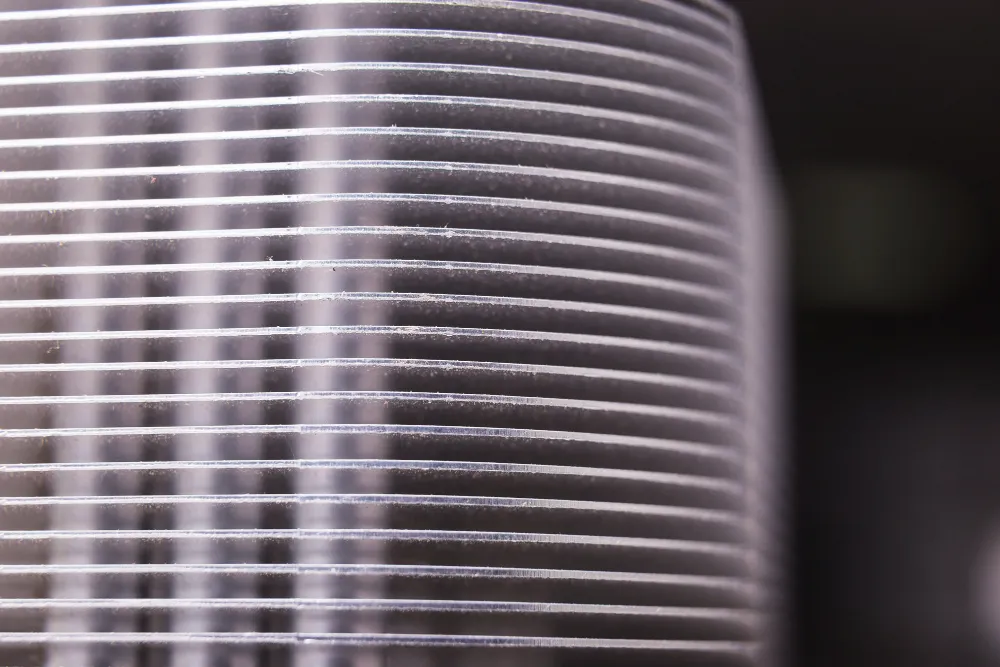

The units employ flat aluminum multi-port tubes arranged in a true counter-flow pattern. Each

tube contains ninety ports 0.7 mm wide, creating internal surface densities above 1 500 m² m⁻³

and pushing overall heat-transfer coefficients beyond 5 kW m⁻² K⁻¹ for water-to-water duty. The

result is a microchannel heat exchanger that achieves 3 K approach temperature in 40 % less

footprint while keeping water-side pressure loss below 25 kPa, so existing pumps need no

upgrade.

Kaltra vacuum-brazes every joint at 600 °C under nitrogen, fusing tube and fin into a single

aluminum block rated 30 bar and 200 °C. The monolithic core passes 650 h neutral salt-spray

without pitting, giving the microchannel heat exchanger a 20-year design life in coastal or urban

atmospheres without protective coatings. Weight drops by 200 kg per 500 kW section, allowing

roof-mounted skids to remain within original load limits.

Counter-Flow Core Lifts Make-Up Water from 40 °C to 70 °C without Pump Upgrade

For sites where chloride exceeds 1 mg m⁻³, fins can receive 12 µm cathodic epoxy through an

electrophoretic process that survives 2 000 h salt-spray yet adds only 3 Pa extra pressure drop, so

capacity derating is unnecessary.

Kaltra https://www.kaltra.com/microchannel-heat-exchangers sizes each unit through an AI

portal trained on 50 000 laboratory tests. Enter hot and cold flow rates, approach temperature

and footprint; validated effectiveness, pressure drop and live price are returned in sixty seconds,

together with STEP and ERP export files. Production capacity reaches one million cores per year

across facilities in Graz and Plzeň, with fourteen vacuum-brazing furnaces operating 24/7.

Standard lead time is ten working days; emergency batches ship in seventy-two hours, pressure-

tested to 52 bar and dried to −40 °C dew point.

By converting low-grade waste heat into usable energy, plants cut fuel bills and CO₂ emissions in a

single upgrade, proving that microchannel heat exchangers are the quiet heart of modern energy

recovery.